TEN.blog

We talk about design and sustainability.2009 work in progress

For the exhibition 2009 at 100% Design, we have Metropolitan Works as our partner. TEN goes Digital this year.

Issues are the same as last three years – how we can encourage sustainable life through objects/products/ways of commnications. Now we have opportunity to think how to apply the latest digital manufacturering for this context.

Here are some works in progress.

< last up-dated 23 September 2009 >

Chris Jackson

< Digital Readymades >

My project aims to reinvigorate broken or discarded objects, and re-appropriate existing objects, to extend their lives. The traditional readymade with a digital twist. The project utilises digital technologies, including laser cutting and rapid prototyping, which are accessible to the general public through online resources including Ponoko and Shapeways.

These objects currently include cheap solar garden lamps, broken USB keys and a hot water bottle.

The project aims to explore manufacturing on demand (as opposed to mass manufacture), open source design and hacking as contemporary responses to the subject of sustainable design, as well as raising awareness of the possibilities of these resources.

This project is supported by:

www.ponoko.com

www.shapeways.com

Gitta Gschwendtner

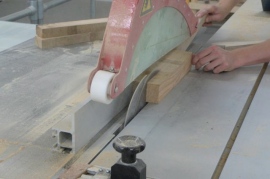

I have travelled to Benchmarks factory to collect timber off-cuts from their wood workshop. The plan is to reuse this solid timber which would ordinarily end up as heating material for the winter.

The wood I have collected is too short too be planed and had to be cut by circular saw into 3 cm strips to create blocks which can be glued up into a stack.

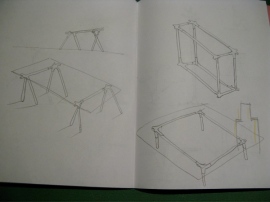

The plan then was to use the 5-axis cnc machine to mill two stools from the two stacks. One is a 3D scan of a tree trunk, gesturing towards the timbers origin. The process is proving very difficult due to a number of issues and it is not clear at this stage whether the stool will make it to 100% Design. Here is the scan of the trunk and an image of what one half looks like now. More abstract then I thought, but how legible the trunk was going to be was always part of the experiment.

The second stool has a much simpler shape, purposefully giving the eye an easier task to fill in the ‘gaps’. The stool is still on the cnc machine, lets hope it works. This is the file that it is being milled from.

Michael Marriott

< shelving system, made using reclaimed timber panels fixed together with brass brackets.>

I’m working on a shelving system, that uses reclaimed timber panels, (solid wood, plywood, chipboard,) This would typically be a cheap particleboard cabinet, that has failed structurally, and left on the street.

The key to making this into new shelving is a small bracket, that allows for simple construction with a screwdriver.

The bracket has been generated in Solidworks, then rapid prototyped by Met Wrks as a nylon SLS. This model is then finished by hand ready to make a mould from for wax castings. The finished components will be lost wax cast in brass, a material which has always been recycled, and is also 100% recyclable.

sls

spraying

sanding

silicone mould

castings

Nina Tolstrup

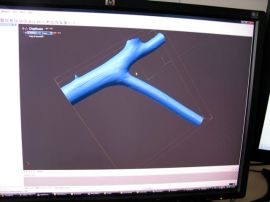

< series of furniture made of joints, made out of scanned twig and bloom sticks >

Q. Which digital technology are you using?

A. 3D scanning, rapid prototype for the mould making

Q. What is your latest development?

A. I’m trying to figure out how to manipulate the mesh of the 3D scan, which seems to be more complicated that I had imagined.

Following images are the latest work in progress, posted on 18 September.

Tomoko Azumi

< bird house and feeder made by reclaimed roof tiles >

Q. Which digital technology are you using?

A. Water-jet cutter and Laser cutting & engraving

Q. Sustainable aspects?

A. Reclaiming odd roof-top tiles, which are often not used again. Water-jst cutter makes them in usable size to other items – such as birds house. Facade of birds house is referring Victorian houses to apperciate history of the tile. Those patterns are engraved when the board is cut in shape in a single stage.

Q. What is the latest development?

A. I am working on two things – adjust house size correct for common birds in Europe and find most appropriate material for the wall, yet make the laser engrave works on it.

This is latest photo (18 Sep 2009)

Stephen Bretland

In the 1990’s I spent a lot of time working as a model-maker. We didn’t have any CAD machinery back then. It was always a big effort to make models accurately by hand. Now, I prefer my design work to be more relaxed, rougher and not so accurate. The odd mistake or flaw has a human quality to it showing clear traces and evidence of the making process.

I don’t care too much about the accuracy achievable with CAD technology. I have really only used Met works as a prototyping facility on this occasion. For the project TEN XYZ, I have designed 3 products that could be made with older and simpler technology. In other words if they went into production they could be CNC milled/water jet cut or made in a small workshop with older kit and jigs

Salad server > based on toy robot arms. Designed to encourage children to engage with salad (and perhaps eat some). Made on a 3 axis milling machine.

Fruit bowl > Base is a beech disc with 24 slots. The sides of the bowl are made from pencils. Half of the object is made from pencils or pens that people already have. Made on a 3 axis milling machine.

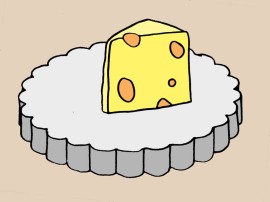

Marble cheeseboard > I took the opportunity to try something new. I made use of the water jet cutter at Met works, this allowed me to design a simple product in marble. The design is based on a well known cracker.

They tried a cnc version too.

I find 3 axes plenty.

2 Comments»

[…] our .2009 in progress […]

i do enjoy your work and love tenproject as whole.